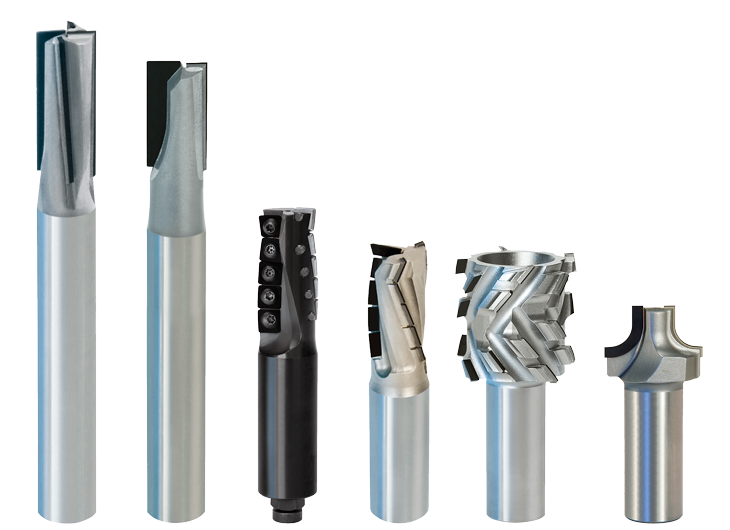

Diamond Milling Cutters

DIATEC- end mills

The following tools from the diamond tool program are characterized by special features.

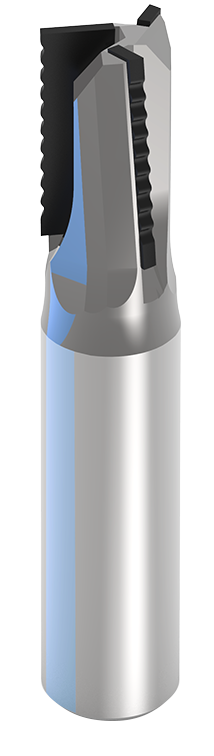

- stable tools due to carbide base body

- cutting free of offsets due to the continuous pairing of cutting edges

- large flutes

- sharp-edged and tear-free workpiece upper and lower edges due to the alternating arrangement of the cutting edges

- wide range of application of the tools: wood materials, plastics, mineral materials and aluminum

- stable cutting geometry

- easy to service. "Straight cutting edges are easier to sharpen".

- optimum rake angle ratios - this means that consistently long tool lives can be expected

*****

Diastart-UNO

| D (mm) |

L2 (mm) |

L4 (mm) |

L1 (mm) |

S (mm) |

Part-No. |

|---|---|---|---|---|---|

| 10 | 26 | 9,2 | 75 | 12x40 | 12100-9-10262-L |

| 12 | 26 | 9,2 | 75 | 12x40 | 12100-9-10262-R |

| 12 | 26 | 9,2 | 75 | 12x40 | 12100-9-12262-L |

| 12 | 26 | 9,2 | 75 | 12x40 | 12100-9-12262-R |

| 12 | 26 | 9,2 | 80 | 16x45 | 12100-9-12263-L |

| 12 | 26 | 9,2 | 80 | 16x45 | 12100-9-12263-R |

| 12 | 35 | 9,2 | 85 | 12 x 40 | 12100-9-12352-L |

| 12 | 35 | 9,2 | 85 | 12 x 40 | 12100-9-12352-R |

| 12,7 | 26 | 9,2 | 75 | 12,7 x 40 | 12100-9-12726-L |

| 12,7 | 26 | 9,2 | 75 | 12,7 x 40 | 12100-9-12726-R |

| 15,88 | 35 | 9,2 | 90 | 15,88 x 45 | 12100-9-15835-L |

| 15,88 | 35 | 9,2 | 90 | 15,88 x 45 | 12100-9-15835-R |

| 16 | 26 | 9,2 | 80 | 16 x 45 | 12100-9-16263-L |

| 16 | 26 | 9,2 | 80 | 16 x 45 | 12100-9-16263-R |

| 16 | 35 | 9,2 | 90 | 16 x 45 | 12100-9-16353-L |

| 16 | 35 | 9,2 | 90 | 16 x 45 | 12100-9-16353-R |

| 16 | 35 | 9,2 | 105 | 25 x 60 | 12100-9-16356-L |

| 16 | 35 | 9,2 | 105 | 25 x 60 | 12100-9-16356-R |

| 18 | 26 | 9,2 | 90 | 20 x 55 | 12100-9-18265-L |

| 18 | 26 | 9,2 | 90 | 20 x 55 | 12100-9-18265-R |

| 18 | 35 | 9,2 | 100 | 20 x 55 | 12100-9-18355-L |

| 18 | 35 | 9,2 | 100 | 20 x 55 | 12100-9-18355-R |

| 18 | 43 | 9,2 | 115 | 25 x 60 | 12100-9-18436-L |

| 18 | 43 | 9,2 | 115 | 25 x 60 | 12100-9-18436-R |

| 19,05 | 43 | 9,2 | 115 | 25,4 x 60 | 12100-9-19054-L |

| 19,05 | 43 | 9,2 | 115 | 25,4 x 60 | 12100-9-19054-R |

| 20 | 26 | 9,2 | 95 | 25 x 60 | 12100-9-20266-L |

| 20 | 26 | 9,2 | 95 | 25 x 60 | 12100-9-20266-R |

| 20 | 52 | 9,2 | 120 | 25 x 60 | 12100-9-20526-L |

| 20 | 52 | 9,2 | 120 | 25 x 60 | 12100-9-20526-R |

| 25 | 26 | 9,2 | 95 | 25 x 60 | 12100-9-25266-L |

| 25 | 26 | 9,2 | 95 | 25 x 60 | 12100-9-25266-R |

| 25 | 52 | 9,2 | 120 | 25 x 60 | 12100-9-25526-L |

| 25 | 52 | 9,2 | 120 | 25 x 60 | 12100-9-25526-R |

12100

Technical details:

- tool body made of steel

- burnished

- periphery tips and plunge tip made from pcd

- alternative shear cut

- several times regrindable

- without length adjusting screw

- tipping height: 2,5 mm

Application:

- grooving, sizing, severing and rebating of classically wood composites

- suitable for axial and ramp plunge cutting

Special advantages:

- cost effective

- PCD-plunge tip also cutting on periphery (Z2)

- Dianova tip seat design

Application data:

R.P.M. = 18 000 - 24 000

vf = 3 - 7 m/min

*****

Diatec-DUO Finishing Cutters

| D (mm) |

L2 (mm) |

L3 (mm) |

L (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|---|

| 5 | 10 | 12 | 50 | 6 | 14250-9-05100-R |

| 6 | 15 | 20 | 65 | 6 | 14250-9-06150-R |

| 8 | 15 | 20 | 65 | 8 | 14250-9-08150-R |

| 8 | 20 | 25 | 70 | 8 | 14250-9-08200-R |

| 10 | 10 | 15 | 75 | 10 | 14250-9-10100-R |

| 10 | 15 | 20 | 75 | 10 | 14250-9-10150-R |

| 10 | 20 | 25 | 80 | 10 | 14250-9-10200-R |

| 12 | 15 | 20 | 70 | 12 | 14250-9-12152-R |

| 12 | 20 | 25 | 75 | 12 | 14250-9-12202-R |

| 12 | 25 | 29 | 75 | 12 | 14250-9-12252-R |

| 12 | 30 | 35 | 80 | 12 | 14250-9-12302-R |

| 16 | 10 | 20 | 80 | 16 | 14250-9-16103-R |

| 16 | 15 | 25 | 80 | 16 | 14250-9-16153-R |

| 16 | 20 | 25 | 80 | 20 | 14250-9-16205-R |

| 16 | 25 | 30 | 85 | 16 | 14250-9-16253-R |

| 18 | 15 | 25 | 80 | 18 | 14250-9-18155-R |

| 18 | 20 | 25 | 80 | 18 | 14250-9-18205-R |

| 20 | 20 | 30 | 85 | 20 | 14250-9-20205-R |

14250

Technical details

- tool body made of steel (*) or solid tungsten carbide

- periphpery tips and plunge tip made from pcd

- alternative shear cut

- several times regrindable

Application

- finishing, grooving, sizing, severing (nesting) and rebating of particularly abrasive workpiece materials

- applicable for axial- and ramp plunge cutting

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fibreboards

- solid- and glued wood

- limited usable in Aluminum

Spezial advantages: continous cutting edges for line-free cut

Application data:

Heat-setting material/Thermoplastics / HPL: R.P.M. = 15 000 - 22 000, vf = 1 - 5 m/min

Solid surface: R.P.M. = 15 000 - 22 000, vf = 4 - 8 m/min

Wood based panels: R.P.M. = 18 000 - 24 000, vf = 6 - 9 m/min

*****

DIATEC-TRIO-Finshing Cutters Z3

| D (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|---|

| 12 | 10 | 19 | 70 | 12 | 14253-9-12102-R |

| 12 | 15 | 24 | 70 | 12 | 14253-9-12152-R |

| 12 | 20 | 29 | 75 | 12 | 14253-9-12202-R |

| 12 | 25 | 34 | 80 | 12 | 14253-9-12252-R |

| 14 | 15 | 23 | 70 | 14 | 14253-9-14151-R |

| 14 | 20 | 28 | 75 | 14 | 14253-9-14201-R |

| 14 | 25 | 33 | 80 | 14 | 14253-9-14251-R |

| 16 | 10 | 25 | 80 | 16 | 14253-9-16103-R |

| 16 | 15 | 30 | 80 | 16 | 14253-9-16153-R |

| 16 | 20 | 30 | 80 | 16 | 14253-9-16203-R |

| 16 | 25 | 30 | 80 | 16 | 14253-9-16253-R |

| 16 | 30 | 35 | 85 | 16 | 14253-9-16303-R |

| 16 | 35 | 40 | 90 | 16 | 14253-9-16353-R |

| 20 | 10 | 15 | 85 | 16 | 14253-9-20105-R |

| 20 | 15 | 20 | 85 | 16 | 14253-9-20155-R |

| 20 | 20 | 25 | 85 | 20 | 14253-9-20205-R |

| 20 | 25 | 30 | 90 | 20 | 14253-9-20255-R |

| 20 | 30 | 35 | 95 | 20 | 14253-9-20305-R |

14253

Technial details

- tool body made of solid tungsten carbide

- periphery tips and plunge tip made from pcd

- alternative shear cut (2 negative; 1 positive)

- several times regrindable

Application

- finishing, grooving, sizing, severing (nesting) and rebating of particularly abrasive workpiece materials

- applicable for axial- and ramp plunge cutting

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fibreboards

- solid- and glued wood

Special advantages: continious cutting edges for line-free cut

Application data:

* Heat-setting material/Thermoplastics / HPL: R.P.M. = 15 000 - 18 000, vf = 3 - 8 m/min

* Solid surface: R.P.M. = 15 000 - 18 000, vf = 6 - 10 m/min

* Wood based panels: R.P.M. = 18 000 - 24 000, vf = 12 - 20 m/min

*****

Diatec-TRIO Roughing Cutters Z3

| D (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

S (mm) |

Part-No.: |

|---|---|---|---|---|---|

| 12 | 10 | 19 | 70 | 12 | 14256-9-12102-R |

| 12 | 15 | 24 | 70 | 12 | 14256-9-12152-R |

| 12 | 20 | 29 | 75 | 12 | 14256-9-12202-R |

| 12 | 25 | 34 | 80 | 12 | 14256-9-12252-R |

| 14 | 15 | 23 | 70 | 14 | 14256-9-14151-R |

| 14 | 20 | 28 | 75 | 14 | 14256-9-14201-R |

| 14 | 25 | 33 | 80 | 14 | 14256-9-14251-R |

| 16 | 10 | 25 | 80 | 16 | 14256-9-16103-R |

| 16 | 15 | 30 | 80 | 16 | 14256-9-16153-R |

| 16 | 20 | 30 | 80 | 16 | 14256-9-16203-R |

| 16 | 25 | 30 | 80 | 16 | 14256-9-16253-R |

| 16 | 30 | 35 | 85 | 16 | 14256-9-16303-R |

| 16 | 35 | 40 | 90 | 16 | 14256-9-16353-R |

| 20 | 10 | 15 | 85 | 16 | 14256-9-20105-R |

| 20 | 15 | 20 | 85 | 16 | 14256-9-20155-R |

| 20 | 20 | 25 | 85 | 20 | 14256-9-20205-R |

| 20 | 25 | 30 | 90 | 20 | 14256-9-20255-R |

| 20 | 30 | 35 | 95 | 20 | 14256-9-20305-R |

14256

Technical details

- tool body made of solid tungsten carbide

- periphery tips and plunge tip made from pcd

- alternative shear cut (2 negative; 1 positive)

- roughing ground

- several times regrindable

Application

- roughing, grooving, sizing, severing (nesting) and rebating of particularly abrasive workpiece materials

- applicable for axial- and ramp plunge cutting

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fibreboards

- solid- and glued wood

Special advantages: roughing ground for increased chip volume and reduced cutting force

Application data:

- Heat-setting material/Thermoplastics / HPL: R.P.M. = 15 000 - 18 000, vf = 5 - 9 m/min

- Solid surface: R.P.M. = 15 000 - 18 000, vf = 8 - 12 m/min

- Wood based panels: R.P.M. = 18 000 - 24 000, vf = 15 - 25 m/min

*****