Tools for thermoplastics and acrylic glas

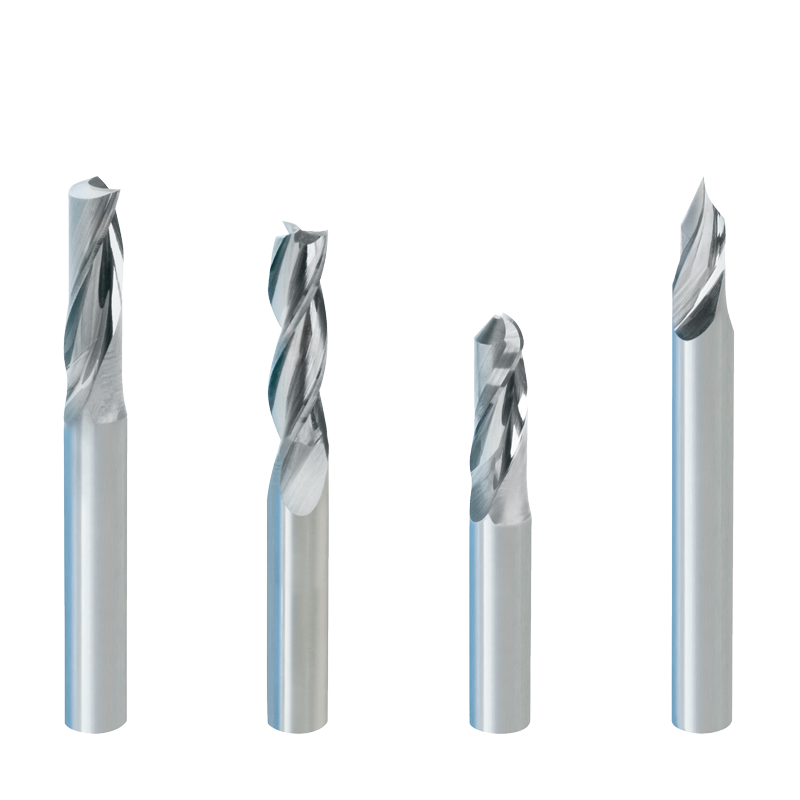

93103 End Mill Cutters solid TC Z1 HW04

| D (mm) |

L2 (mm) |

L1 (mm) |

S (mm) |

Part-No.: |

|---|---|---|---|---|

| 2 | 2 | 50 | 6 | 93103-6-02050-R |

| 4 | 15 | 50 | 6 | 93103-6-04150-R |

| 6 | 20 | 60 | 6 | 93103-6-06200-R |

| 8 | 25 | 70 | 8 | 93103-6-08250-R |

| 10 | 30 | 70 | 10 | 93103-6-10300-R |

93103 HW 04

Technical details

Single tooth solid carbide router cutters made of either standard (HW 04) or micro-grain carbide (HW 08), with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Application

For polish cutting (clearcut milling, grooving, sizing and severing) of thermoplastics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PS (polystyrene), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride). Nearly clearcut surface of the machined edges through pre-cutting against feed and

then finish-cutting (with low chip removal) with feed.

Application data:

Pre-cutting against feed: R.P.M. = 18 000 - 24 000, feed rate vf = 2 - 6 m/min.

Finish-cutting with feed: R.P.M. = 18 000 - 24 000, feed rate vf = 0,1 - 0,4 m/min., lateral adjustement ae = 0,1 mm - 0,3 mm

To avoid heat development resp. stress whitening, we recommend to support the chip removal through compressed air.

*****

93113 End Mill Cutters solid TC Z1 HW08

| D (mm) |

L2 (mm) |

L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|

| 6 | 20 | 60 | 6 | 93113-6-06200-R |

| 8 | 25 | 70 | 8 | 93113-6-08250-R |

93113 HW 08

Technical details

Single tooth solid carbide router cutters made of either standard (HW 04) or micro-grain carbide (HW 08), with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Application

For polish cutting (clearcut milling, grooving, sizing and severing) of thermoplastics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PS (polystyrene), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride). Nearly clearcut surface of the machined edges through pre-cutting against feed and

then finish-cutting (with low chip removal) with feed.

Application data:

Pre-cutting against feed: R.P.M. = 18 000 - 24 000, feed rate vf = 2 - 6 m/min.

Finish-cutting with feed: R.P.M. = 18 000 - 24 000, feed rate vf = 0,1 - 0,4 m/min., lateral adjustement ae = 0,1 mm - 0,3 mm

To avoid heat development resp. stress whitening, we recommend to support the chip removal through compressed air.

*****

93303 Multi-tooth End Mill cutters solid TC Z3 HW04

| D (mm) |

L2 (mm) |

L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|

| 6 | 20 | 50 | 6 | 93303-6-06200-R |

93303 HW 04 Z3

Technical details

Multi tooth solid carbide router cutters with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Applications

For polish cutting (clearcut milling, grooving, sizing and severing) of thermoplastics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PS (polystyrene), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride).

Nearly clearcut surface of the machined edges through pre-cutting against feed and then finish-cutting (with low chip removal) with feed.

Application data:

Rough-cutting: R.P.M. = 18 000 - 24 000, feed rate vf = 6 - 10 m/min. (Z3) resp. 8 - 15 m/min. (Z5)

Finish-cutting with feed: R.P.M. = 18 000 - 24 000, feed rate vf = 0,3 - 0,8 m/min., lateral adjustement ae = 0,1 - 0,3 mm

*****

93503 Multi-tooth End Mill cutters solid TC Z5 HW04

| D (mm) |

L2 (mm) |

L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|

| 8 | 30 | 70 | 8 | 93503-6-08300-R |

| 10 | 40 | 70 | 10 | 93503-6-10400-R |

93503 HW 04 Z5

Technical details

Multi tooth solid carbide router cutters with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Applications

For polish cutting (clearcut milling, grooving, sizing and severing) of thermoplastics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PS (polystyrene), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride).

Nearly clearcut surface of the machined edges through pre-cutting against feed and then finish-cutting (with low chip removal) with feed.

Application data:

Rough-cutting: R.P.M. = 18 000 - 24 000, feed rate vf = 6 - 10 m/min. (Z3) resp. 8 - 15 m/min. (Z5)

Finish-cutting with feed: R.P.M. = 18 000 - 24 000, feed rate vf = 0,3 - 0,8 m/min., lateral adjustement ae = 0,1 - 0,3 mm

*****

96113 Ball Nose Cutters solid TC Z1 HW04

| D (mm) |

L2 (mm) |

R (mm) |

L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|---|

| 2 | 5 | 1 | 50 | 6 | 96113-6-02050-R |

| 4 | 15 | 2 | 50 | 6 | 96113-6-04150-R |

| 6 | 20 | 3 | 60 | 6 | 96113-6-06200-R |

| 8 | 25 | 4 | 70 | 8 | 96113-6-08250-R |

| 10 | 30 | 5 | 70 | 10 | 96113-6-10300-R |

96113 HW 04

Technical details

Single tooth solid carbide router cutters with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Applications

For machining (lettering, cove cutting, 3D-cutting, sizing, severing and drilling) of thermoplastics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PS (polystyrol), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride).

Application data:

Pre-cutting: R.P.M. = 16 000 - 24 000, feed rate vf = 2 - 6 m/min.

Finish-cutting with feed: R.P.M. = 16 000 - 24 000, feed rate vf = 0,3 - 0,6 m/min., axial adjustement ap = 0,5 - 1,0 mm

Drilling: R.P.M. = 16 000 - 24 000, feed rate vf = 0,5 - 1,0 m/min.

*****

96123 V-Groove Cutters solid TC Z1 HW04

| D (mm) |

L2 / L3 (mm) |

Grad | L1 (mm) |

S (mm) |

Part.-No.: |

|---|---|---|---|---|---|

| 6 | 10 / 5 | 60° | 60 | 6 | 96123-6-06600-R |

| 6 | 10 / 3 | 90° | 60 | 6 | 96123-6-06900-R |

96123 HW 04

Technical details

Single tooth solid carbide router cutters with special cutting edge geometry for the best surface quality. With polished flutes and also with polished clearance for optimum chip removal and superior cutting results. Right-hand rotation - up-cut.

Application

For machining (lettering, mitre folding and bevelling) of thermoplasics e.g. PMMA (acrylic glass), PC (polycarbonate), PE (polyethylene), PS (polystyrol), ABS (acrylonitrile-butadiene-styrene) and PVC (polyvinyl chloride).

Application data:

Pre-cutting: R.P.M. = 18 000 - 24 000, feed rate vf = 2 - 6 m/min

Finish-cutting: R.P.M. = 18 000 - 24 000, feed rate vf = 0,3 - 0,6 m/min., axial adjustement ap = 0,5 - 1,0 mm