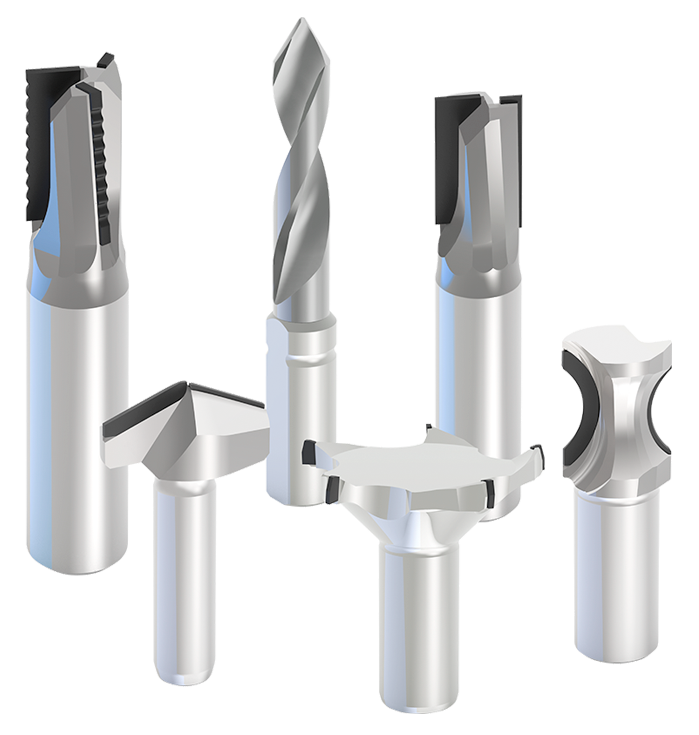

Tools for Machining HPL

What is HPL?

HPL stands for High Pressure Laminate. HPL laminates, formed under high pressure, are made of paper, wood fibres and melamine resin or decorative paper. During production, layers of paper are pressed together with melamine resin at over 5 MPa pressure and 120°C.

What are the properties of HPL materials?

HPL laminated panels are non-deformable and highly resistant to temperature (up to 180°C). At the same time, the material is extremely weather resistant. Other advantages

include fire safety and resistance to impacts and scratching.

Where is HPL used?

HPL sheets are ideal both for outdoor and indoor use. Applications range from facade cladding and garden furniture to interior partition walls and shower panels.

How are HPL materials processed?

HPL panels are more difficult to machine than other materials. Thus it is extremely important to use the most appropriate tool for the particular machining application.

With quality tools from JSO which have been specially developed for HPL machining, you can work precisely and effectively, thus ensuring consistently high quality.

*****

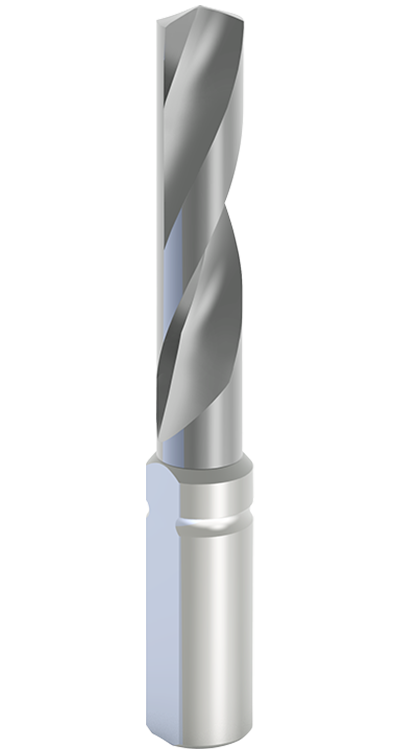

PCD Dowel Drills

| D (mm) |

L2 (mm) |

L4 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 8 | 27 | 2,6 | 57,5 | 10 | 30540-9-08025-L |

| 8 | 27 | 2,6 | 57,5 | 10 | 30540-9-08025-R |

| 8 | 35 | 2,6 | 70 | 10 | 30540-9-08035-L |

| 8 | 35 | 2,6 | 70 | 10 | 30540-9-08035-R |

| 10 | 35 | 3,2 | 70 | 10 | 30540-9-10035-L |

| 10 | 35 | 3,2 | 70 | 10 | 30540-9-10035-R |

| 12 | 35 | 3,9 | 70 | 10 | 30540-9-12035-L |

| 12 | 35 | 3,9 | 70 | 10 | 30540-9-12035-R |

Technical details:

- sturdy drill body, PCD tipped

- flat peak design with double bevel for tear-free blind holes

- shank with clamping flat and length adjusting screw

Application:

- for drilling blind - and through holes

- perfect machining on nesting machines

- espacially applicable for abrasive workpiece materials

- for use on CNC machines and on throughfeed drillingmachines

Workpiece materials:

- cement bounded and fi re resistant board materials

- fibre-reinforced synthetic materials (FVK)

- HPL (TRESPA®, laminate, RESOPAL®)

- multiplex

- laminated chipboard and MDF

*****

Dowel Drills - solid TC

| D (mm) |

L2 (mm) |

L4 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 3 | 20 | 0,5 | 57,5 | 10 | 30559-6-03020-L |

| 3 | 20 | 0,5 | 57,5 | 10 | 30559-6-03020-R |

| 4 | 23 | 0,7 | 57,5 | 10 | 30559-6-04023-L |

| 4 | 23 | 0,7 | 57,5 | 10 | 30559-6-04023-R |

| 5 | 23 | 0,9 | 57,5 | 10 | 30559-6-05023-L |

| 5 | 23 | 0,9 | 57,5 | 10 | 30559-6-05023-R |

| 6 | 25 | 1,1 | 57,5 | 10 | 30559-6-06025-L |

| 6 | 25 | 1,1 | 57,5 | 10 | 30559-6-06025-R |

| 8 | 25 | 1,5 | 57,5 | 10 | 30559-6-08025-L |

| 8 | 25 | 1,5 | 57,5 | 10 | 30559-6-08025-R |

| 10 | 25 | 1,8 | 57,5 | 10 | 30559-6-10025-L |

| 10 | 22 | 1,8 | 57,5 | 10 | 30559-6-10025-R |

| 3 | 22 | 0,5 | 70 | 10 | 30559-6-03022-L |

| 3 | 28 | 0,5 | 70 | 10 | 30559-6-03022-R |

| 4 | 28 | 0,7 | 70 | 10 | 30559-6-04028-L |

| 4 | 36 | 0,7 | 70 | 10 | 30559-6-04028-R |

| 5 | 36 | 0,9 | 70 | 10 | 30559-6-05036-L |

| 5 | 38 | 0,9 | 70 | 10 | 30559-6-05036-R |

| 6 | 38 | 1,1 | 70 | 10 | 30559-6-06038-L |

| 6 | 38 | 1,1 | 70 | 10 | 30559-6-06038-R |

| 8 | 38 | 1,5 | 70 | 10 | 30559-6-08038-L |

| 8 | 38 | 1,5 | 70 | 10 | 30559-6-08038-R |

| 10 | 38 | 1,8 | 70 | 10 | 30559-6-10038-L |

| 10 | 38 | 1,8 | 70 | 10 | 30559-6-10038-R |

Technical details:

- solid TC spiral with 140° V-point

- shank with clamping fl at and length adjusting screw

Application:

- for drilling through holes (on nesting machines) and blind holes in wooden - and platic materials

- for use on CNC machines and on throughfeed drilling machines

Workpiece materials:

- HPL (TRESPA®, laminate, RESOPAL®)

- laminated chipboard and MDF

- multiplex

- solid wood

*****

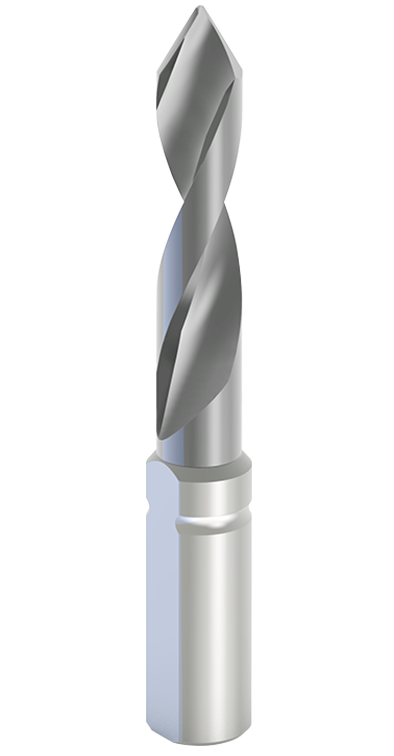

Dowel Drills - solid TC for through holes

| D (mm) |

L2 (mm) |

L4 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 3 | 27 | 2,6 | 57,5 | 10 | 30566-6-03027-L |

| 3 | 27 | 2,6 | 57,5 | 10 | 30566-6-03027-R |

| 4 | 20 | 3,5 | 57,5 | 10 | 30573-6-04020-L |

| 4 | 20 | 3,5 | 57,5 | 10 | 30573-6-04020-R |

| 5 | 20 | 4,3 | 57,5 | 10 | 30573-6-05020-L |

| 5 | 20 | 4,3 | 57,5 | 10 | 30573-6-05020-R |

| 6 | 20 | 5,2 | 57,5 | 10 | 30573-6-06020-L |

| 6 | 20 | 5,2 | 57,5 | 10 | 30573-6-06020-R |

| 8 | 20 | 6,9 | 57,5 | 10 | 30573-6-08020-L |

| 8 | 20 | 6,9 | 57,5 | 10 | 30573-6-08020-R |

| 10 | 20 | 8,7 | 57,5 | 10 | 30573-6-10020-L |

| 10 | 20 | 8,7 | 57,5 | 10 | 30573-6-10020-R |

| 3 | 27 | 2,6 | 70 | 10 | 30566-6-03070-L |

| 3 | 27 | 2,6 | 70 | 10 | 30566-6-03070-R |

| 4 | 25 | 3,5 | 70 | 10 | 30573-6-04025-L |

| 4 | 25 | 3,5 | 70 | 10 | 30573-6-04025-R |

| 5 | 33 | 4,3 | 70 | 10 | 30573-6-05033-L |

| 5 | 33 | 4,3 | 70 | 10 | 30573-6-05033-R |

| 6 | 33 | 5,2 | 70 | 10 | 30573-6-06033-L |

| 6 | 33 | 5,2 | 70 | 10 | 30573-6-06033-R |

| 8 | 33 | 6,9 | 70 | 10 | 30573-6-08033-L |

| 8 | 33 | 6,9 | 70 | 10 | 30573-6-08033-R |

| 10 | 33 | 8,7 | 70 | 10 | 30573-6-10033-L |

| 10 | 33 | 8,7 | 70 | 10 | 30573-6-10033-R |

Technical details:

- solid TC spiral with 60° V-point (D=3 mm; 120°)

- shank with clamping fl at and length adjusting screw

Application:

- for drilling through holes in different kinds fo wood composites and boards

- for use on CNC machines and on throughfeed drilling machines

Workpiece materials:

- HPL (TRESPA®, laminate, RESOPAL®)

- laminated chipboard and MDF

- multiplex

- solid wood

*****

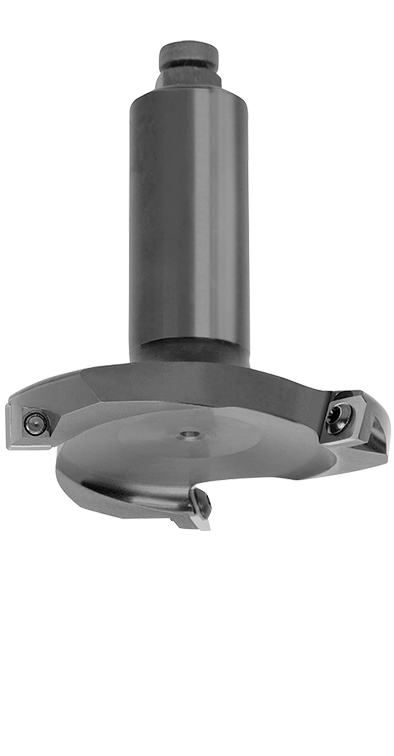

4Cut PCD Surfacing Cutter

| D1 (mm) |

D2 (mm) |

L2 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 82 | 80 | 8 | 80 | 25 | 17525-9-80006-R |

Technical details:

- tool body of high-quality steel with 3 rev PCD tips, 4-sided in special 4Cut design

- positive shear angle

Application:

- for surfacing of working tables and panel raising on all common board - and plastic materials

Workpiece materials:

- HPL (TRESPA®, laminate, RESOPAL®)

- laminated chipboard and MDF

- multiplex

*****

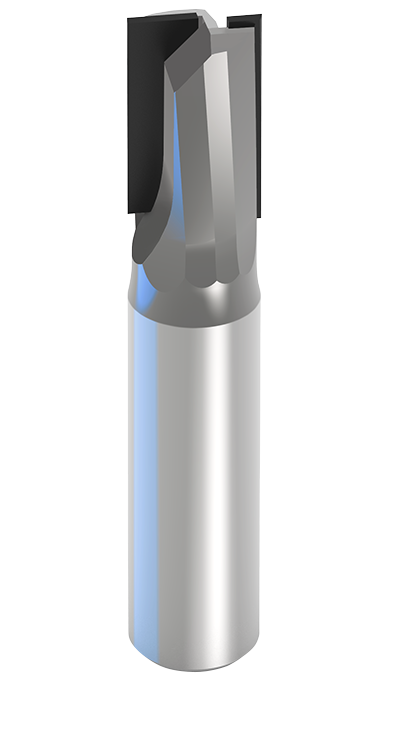

Diatec-DUO Finishing Cutters

| D (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 5 | 10 | 12 | 50 | 6 | 14250-9-05100-R |

| 6 | 15 | 20 | 65 | 6 | 14250-9-06150-R |

| 8 | 15 | 20 | 65 | 8 | 14250-9-08150-R |

| 8 | 20 | 25 | 70 | 8 | 14250-9-08200-R |

| 10 | 10 | 15 | 75 | 10 | 14250-9-10100-R |

| 10 | 15 | 20 | 75 | 10 | 14250-9-10150-R |

| 10 | 20 | 25 | 80 | 10 | 14250-9-10200-R |

| 12 | 15 | 20 | 70 | 12 | 14250-9-12152-R |

| 12 | 20 | 25 | 75 | 12 | 14250-9-12202-R |

| 12 | 25 | 29 | 75 | 12 | 14250-9-12252-R |

| 12 | 30 | 35 | 80 | 12 | 14250-9-12302-R |

| 16 | 10 | 20 | 80 | 16 | 14250-9-16103-R |

| 16 | 15 | 25 | 80 | 16 | 14250-9-16153-R |

| 16 | 20 | 25 | 80 | 20 | 14250-9-16205-R |

| 16 | 25 | 30 | 85 | 16 | 14250-9-16253-R |

| 18 | 15 | 25 | 80 | 18 | 14250-9-18155-R |

| 18 | 20 | 25 | 80 | 18 | 14250-9-18205-R |

| 20 | 20 | 30 | 85 | 20 | 14250-9-20205-R |

Technical details:

- sturdy tool body for high requirements of steel or solid TC

- two continous cutting edges with alternative shear cut and PCD centre tip for plunge cutting

- several times regrindable

Application:

- for finishing, grooving, sizing and rebating of particularly abrasive workpiece materials

- especially applicable for axial and ramp plunge cutting

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

- solid- and glued wood

- limited usable in Aluminum

*****

Diatec-TRIO Finishing Cutters

| D (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 12 | 10 | 19 | 70 | 12 | 14253-9-12102-R |

| 12 | 15 | 24 | 70 | 12 | 14253-9-12152-R |

| 12 | 20 | 29 | 75 | 12 | 14253-9-12202-R |

| 12 | 25 | 34 | 80 | 12 | 14253-9-12252-R |

| 14 | 15 | 23 | 70 | 14 | 14253-9-14151-R |

| 14 | 20 | 28 | 75 | 14 | 14253-9-14201-R |

| 14 | 25 | 33 | 80 | 14 | 14253-9-14251-R |

| 16 | 10 | 25 | 80 | 16 | 14253-9-16103-R |

| 16 | 15 | 30 | 80 | 16 | 14253-9-16153-R |

| 16 | 20 | 30 | 80 | 16 | 14253-9-16203-R |

| 16 | 25 | 30 | 80 | 16 | 14253-9-16253-R |

| 16 | 30 | 35 | 85 | 16 | 14253-9-16303-R |

| 16 | 35 | 40 | 90 | 16 | 14253-9-16353-R |

| 20 | 10 | 15 | 85 | 16 | 14253-9-20105-R |

| 20 | 15 | 20 | 85 | 16 | 14253-9-20155-R |

| 20 | 20 | 25 | 85 | 20 | 14253-9-20205-R |

| 20 | 25 | 30 | 90 | 20 | 14253-9-20255-R |

| 20 | 30 | 35 | 95 | 20 | 14253-9-20305-R |

Technical details:

- tool body made of solid tungsten carbide for high requirements

- three continous cutting edges with alternative shear cut and PCD centre tip for plunge cutting

- several times regrindable

Application:

- for finishing, grooving, sizing and rebating of particularly abrasive workpiece materials

- especially applicable for axial and ramp plunge cutting

- improved feed rate up to 25% compared to Diatec-DUO Z2

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

- solid- and glued wood

*****

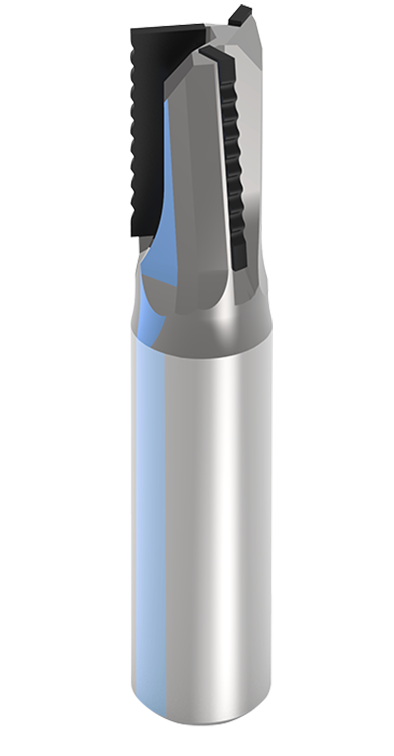

Diatec-TRIO Roughing Cutters

| D (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 12 | 10 | 19 | 70 | 12 | 14256-9-12102-R |

| 12 | 15 | 24 | 70 | 12 | 14256-9-12152-R |

| 12 | 20 | 29 | 75 | 12 | 14256-9-12202-R |

| 12 | 25 | 34 | 80 | 12 | 14256-9-12252-R |

| 14 | 15 | 23 | 70 | 14 | 14256-9-14151-R |

| 14 | 20 | 28 | 75 | 14 | 14256-9-14201-R |

| 14 | 25 | 33 | 80 | 14 | 14256-9-14251-R |

| 16 | 10 | 25 | 80 | 16 | 14256-9-16103-R |

| 16 | 15 | 30 | 80 | 16 | 14256-9-16153-R |

| 16 | 20 | 30 | 80 | 16 | 14256-9-16203-R |

| 16 | 25 | 30 | 80 | 16 | 14256-9-16253-R |

| 16 | 30 | 35 | 85 | 16 | 14256-9-16303-R |

| 16 | 35 | 40 | 90 | 16 | 14256-9-16353-R |

| 20 | 10 | 15 | 85 | 16 | 14256-9-20105-R |

| 20 | 15 | 20 | 85 | 16 | 14256-9-20155-R |

| 20 | 20 | 25 | 85 | 20 | 14256-9-20205-R |

| 20 | 25 | 30 | 90 | 20 | 14256-9-20255-R |

| 20 | 30 | 35 | 95 | 20 | 14256-9-20305-R |

Technical details:

- tool body made of solid tungsten carbide for high requirements

- three continous cutting edges with alternative shear cut and PCD centre tip for plunge cutting

- cutting edges with roughing geometry

- several times regrindable

Application:

- for roughing, grooving, sizing (nesting) and rebating of particularly abrasive workpiece materials

- especially applicable for axial and ramp plunge cutting

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

- solid- and glued wood

*****

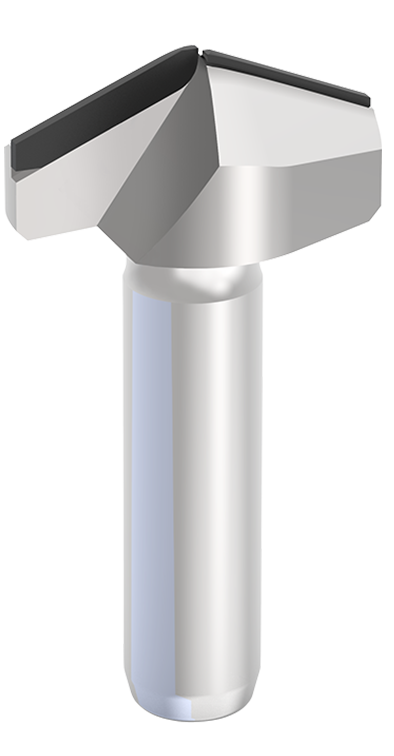

PCD V-Groove / Bevelling Cutters

| D (mm) |

d (mm) |

L2 (mm) |

S (mm) |

Angle | Order number |

|---|---|---|---|---|---|

| 18 | 3 | 7,5 | 12 | 90 | 16010-9-18452-R |

| 32 | 2 | 6,2 | 12 | 135 | 16010-9-32222-R |

| 63 | 3 | 30 | 25 | 90 | 16010-9-63456-R |

| DP-Gravier-Schaftfräser Z1 | |||||

| 14 | 0,5 | 7 | 16 | 90 | 16010-9-14453-R |

Technical details:

sturdy tool body, PCD tipped in Z1 and Z2

Application:

- for bevelling of V-grooves and decorative grooving

- applicable for machining Alucobond boards (excepiton: 16010-9-14453-R)

Workpiece materials:

PCD V-grooving and bevelling cutter:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

- solid- and glued wood

- ALUCOBOND®

- ALUCORE®

PCD decorative grooving cutter 16010-9-14453-R:

- board materials (chipboard, MDF, multiplex)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

*****

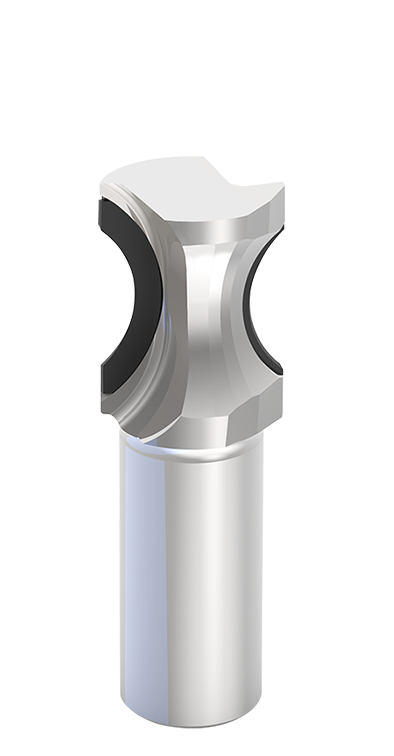

PCD Edge Rounding Cutters

| d (mm) |

D (mm) |

L2 (mm) |

R (mm) |

S (mm) |

Order number |

|---|---|---|---|---|---|

| 18,0 | 31,6 | 24,0 | 16 | 20 | 16030-9-32165-R |

| 19,1 | 23 | 11,9 | 10 | 20 | 16030-9-23105-R |

| 20,0 | 26,0 | 17,0 | 16 | 20 | 16030-9-26165-R |

| 29,2 | 34,8 | 22,2 | 25 | 20 | 16030-9-35255-R |

| DP-Abrundfräser Z2+2 | |||||

| 40,0 | 52,4 | 33,0 | 25 | 20 | 16030-9-52255-R |

Technical details:

sturdy tool body, PCD tipped in Z1 and Z2

Application:

for convex edge rounding

Workpiece materials:

- board materials (chipboard, MDF, multiplex)

- thermoplastics (CFK, GFK, epoxy resin)

- HPL (TRESPA®, laminate, RESOPAL®)

- solid surface (Corian®)

- gypsum fi breboards

- solid- and glued wood

*****